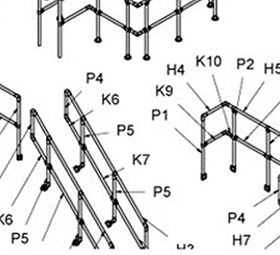

Planning service

Our planning service

For every conceivable design, from shelving systems to security railings, we can delivery you a unique design plan, including the corresponding parts list for the required tubular connectors and cutting lengths of the tubes. In this way, the planning of tubular constructions becomes even easier and can be quickly implemented even under extreme time pressure.

Assembly service

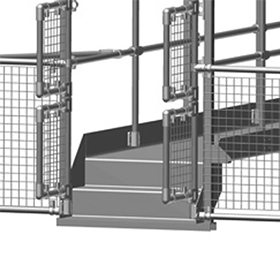

Should you wish to use the advantages of our flexible tubular connector system, but with as low assembly effort as possible at your operating location, then our assembly team can offer an additional service:

Our assembly service

We would be pleased to assemble for you entire assemblies or rail segments according to our parts lists, so that your fitters at the operating location only need to join the pre-assembled segments with our tubular connectors. In this way, you save time on-site and still retain the advantage of our flexible system, which can be customised to the local dimensions at any time.

We are a system supplier to producers of buses and railway vehicles. Tubular connectors, hand rails, turning parts and all accessories are pre-assembled by our assembly team and delivered to the installation site.

All-round support for your product

Consultation

On request, our team can be available to help you right from the planning phase of a new product. We can help you decide on an optimal and economical casting design.

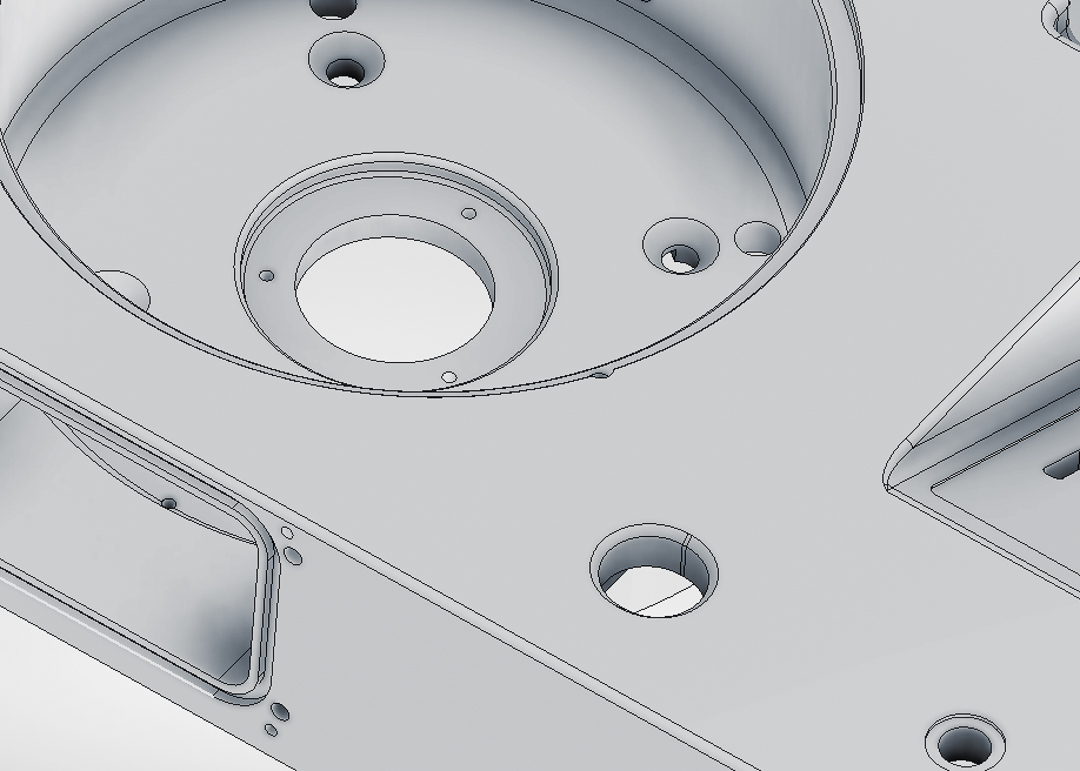

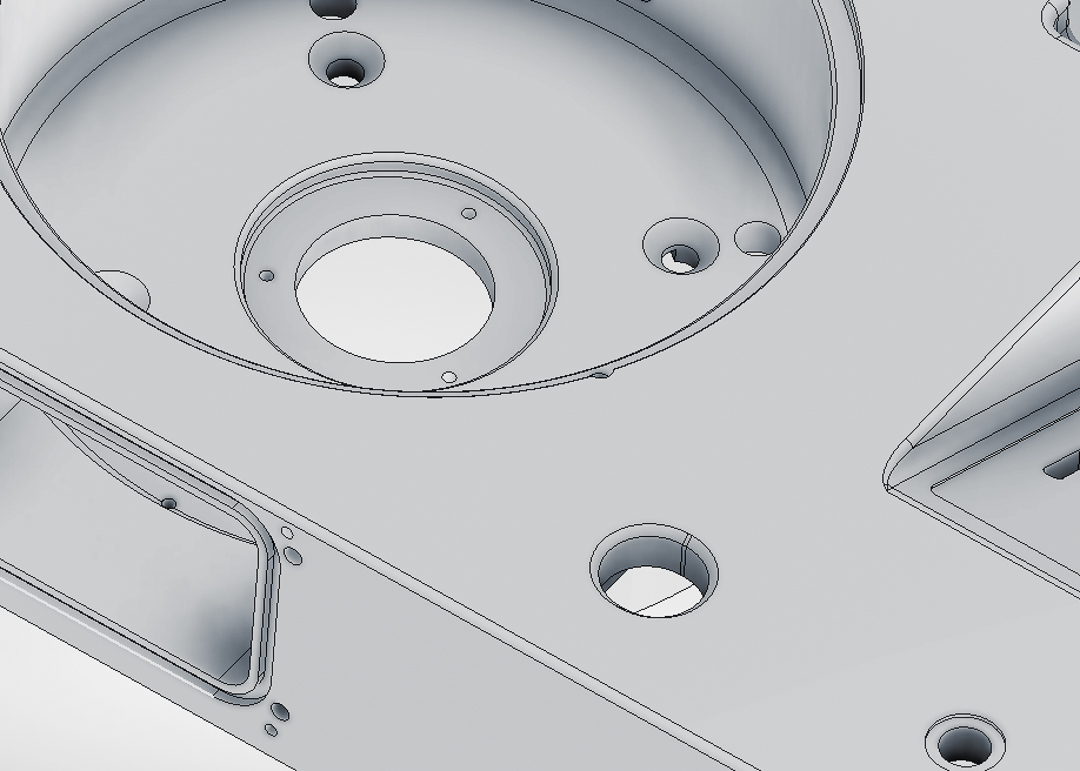

Conception and construction

We develop the moulds and emulation tools for your castings. With 75 years experience in aluminium casting, the close cooperation between our casters, tool designers and design engineers guarantee you an optimal result.

Tool and mould construction

Our tool designers construct, maintain, and service the tools and moulds for your castings. They always ensure top condition of the tools and guarantee their constant availability.

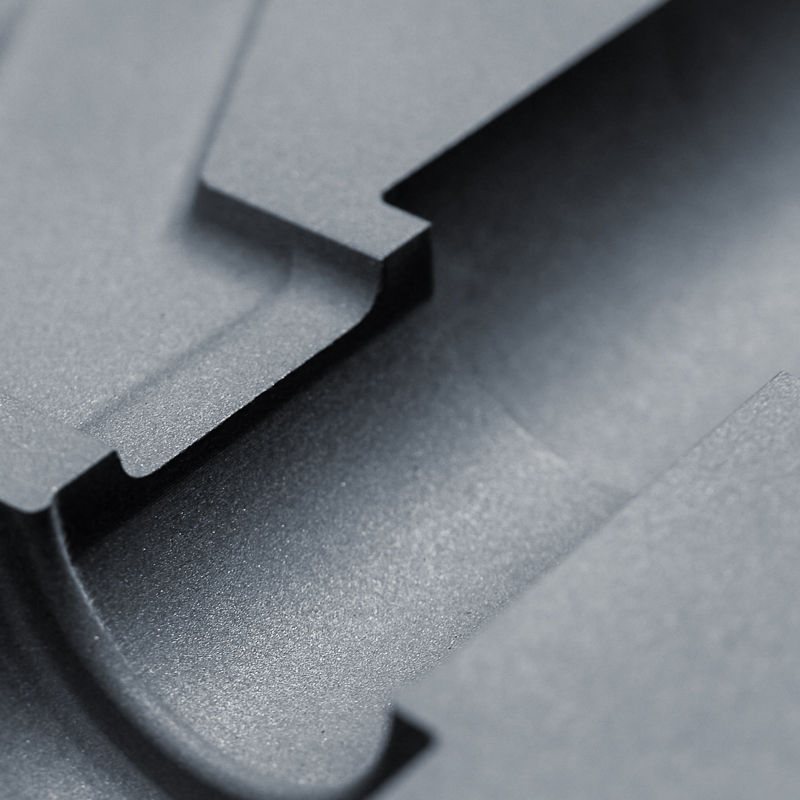

We cast exclusively in mould casting processes

Due to fast heat dissipation, the mould casting has a fine-grained, dense structure with good mechanical properties. This process enables the manufacture of gas and liquid-tight fittings. The cast parts have a high level of dimension accuracy and finish quality and only need to be processed to a very small extent. In addition, the process is very productive.

Process characteristics: along with die casting, mould casting belongs to the precision casting processes. Casts are lowered into metallic permanent moulds in two or more parts for removing the finished cast part. Hollows and indentations are created using grains from metal or sand and shell moulding material. Because of the high thermal conductivity, the mould solidifies the molten material very fast, which results in a fine-grained structure. We have modern facilities with corresponding peripheries, which are either partly or fully-automatically linked to their production units.

| Form: | metallic permanent mould, grains out of metal or moulding material |

| Form durability: | heavily dependent on the mould material, the casting material and the part geometry. With aluminium, up to 100,000 casting cycles are possible. |

| Tolerances approx.: | 0.3 to 0.6 % for light metal alloys, according to DIN 1688 T3. |

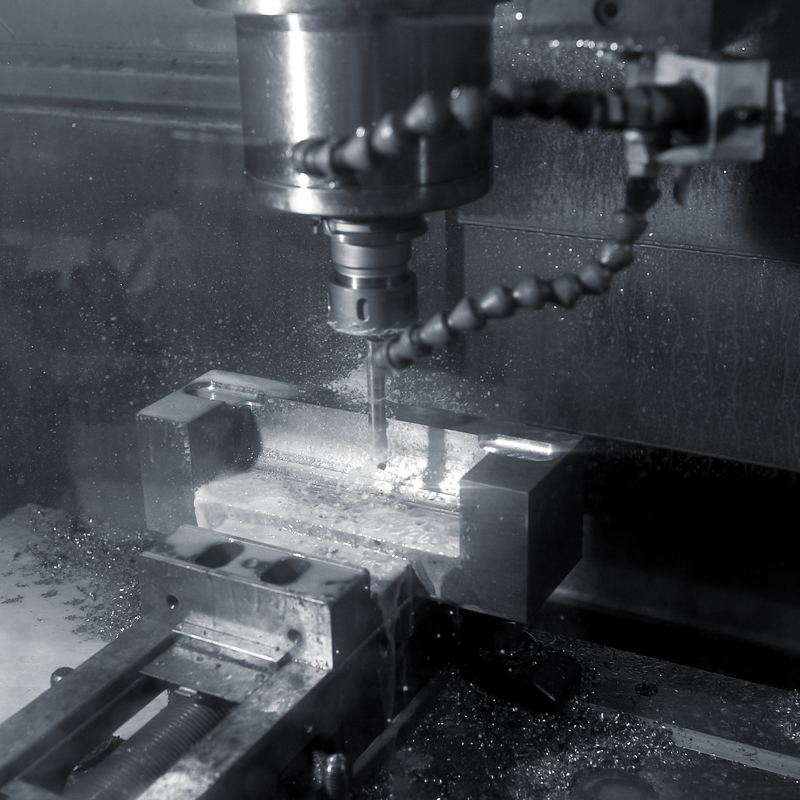

Complete processing

We fully process your casting. Plastering, grinding, turning, milling, drilling and thread cutting to a ready-to-install casting are, for us, a matter of course.

Surface finishing

We finish the surfaces of your castings. You can choose from the following surfaces: untreated (cleanly cast and deburred), polished, trowalised, high-gloss polished, technically anodised, decoratively anodised or colour-coated.

Assembly

Our assembly department completes and assembles your castings to finished products or assemblies. On request, the finished products are provided with your individual packaging and/or company label.

Storage and delivery

We store and commission your manufactured castings with all accessories at your request and ensure that your products arrive at your or your customer site on time. Next to first-class quality, adherence to delivery dates and schedules is for us the most important pre-requisite for a good and long-term cooperation.

All-round support for your product

Beratung

On request, our team can be available to help you right from the planning phase of a new product. We can help you decide on an optimal and economical casting design.

Konzeption und Konstruktion

We develop the moulds and emulation tools for your castings. With 75 years experience in aluminium casting, the close cooperation between our casters, tool designers and design engineers guarantee you an optimal result.

Werkzeug- und Formenbau

Our tool designers construct, maintain, and service the tools and moulds for your castings. They always ensure top condition of the tools and guarantee their constant availability.

Kokillengießverfahren

Due to fast heat dissipation, the mould casting has a fine-grained, dense structure with good mechanical properties. This process enables the manufacture of gas and liquid-tight fittings. The cast parts have a high level of dimension accuracy and finish quality and only need to be processed to a very small extent. In addition, the process is very productive.

Process characteristics: along with die casting, mould casting belongs to the precision casting processes. Casts are lowered into metallic permanent moulds in two or more parts for removing the finished cast part. Hollows and indentations are created using grains from metal or sand and shell moulding material. Because of the high thermal conductivity, the mould solidifies the molten material very fast, which results in a fine-grained structure. We have modern facilities with corresponding peripheries, which are either partly or fully-automatically linked to their production units.

| Form: | metallic permanent mould, grains out of metal or moulding material |

| Form durability: | heavily dependent on the mould material, the casting material and the part geometry. With aluminium, up to 100,000 casting cycles are possible. |

| Tolerances approx.: | 0.3 to 0.6 % for light metal alloys, according to DIN 1688 T3. |

Komplette Bearbeitung

We fully process your casting. Plastering, grinding, turning, milling, drilling and thread cutting to a ready-to-install casting are, for us, a matter of course.

Oberflächenveredelung

We finish the surfaces of your castings. You can choose from the following surfaces: untreated (cleanly cast and deburred), polished, trowalised, high-gloss polished, technically anodised, decoratively anodised or colour-coated.

Montage

Our assembly department completes and assembles your castings to finished products or assemblies. On request, the finished products are provided with your individual packaging and/or company label.

Lagern und liefern

We store and commission your manufactured castings with all accessories at your request and ensure that your products arrive at your or your customer site on time. Next to first-class quality, adherence to delivery dates and schedules is for us the most important pre-requisite for a good and long-term cooperation.